RAW MATERIAL

Pressofusione Bustreo pays great attention to the raw material’s choice. We only use aluminum alloys from certified suppliers.

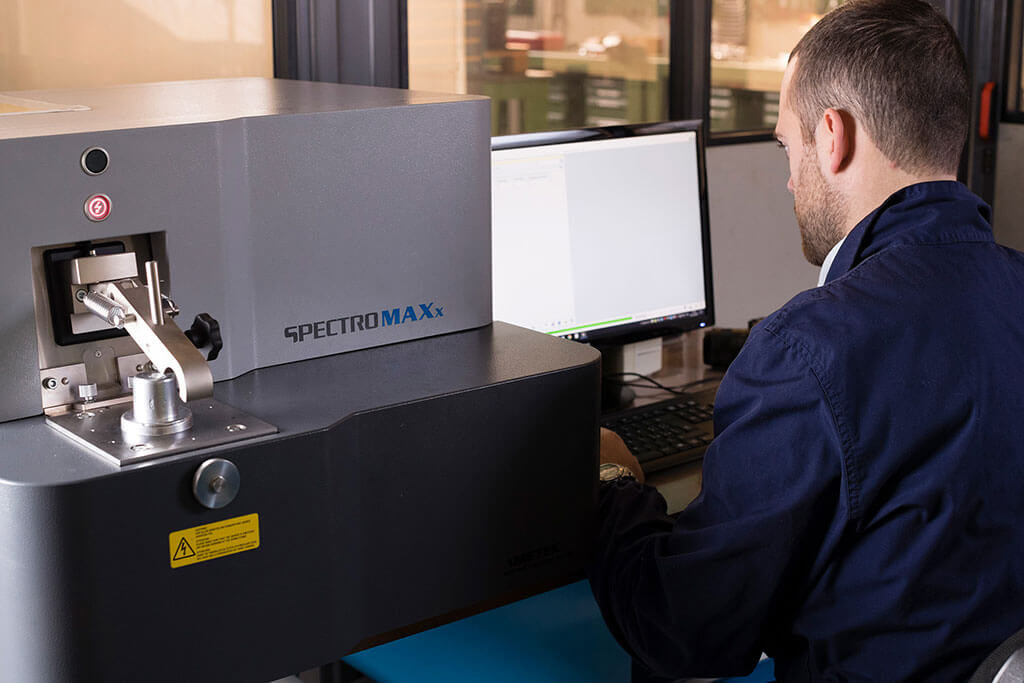

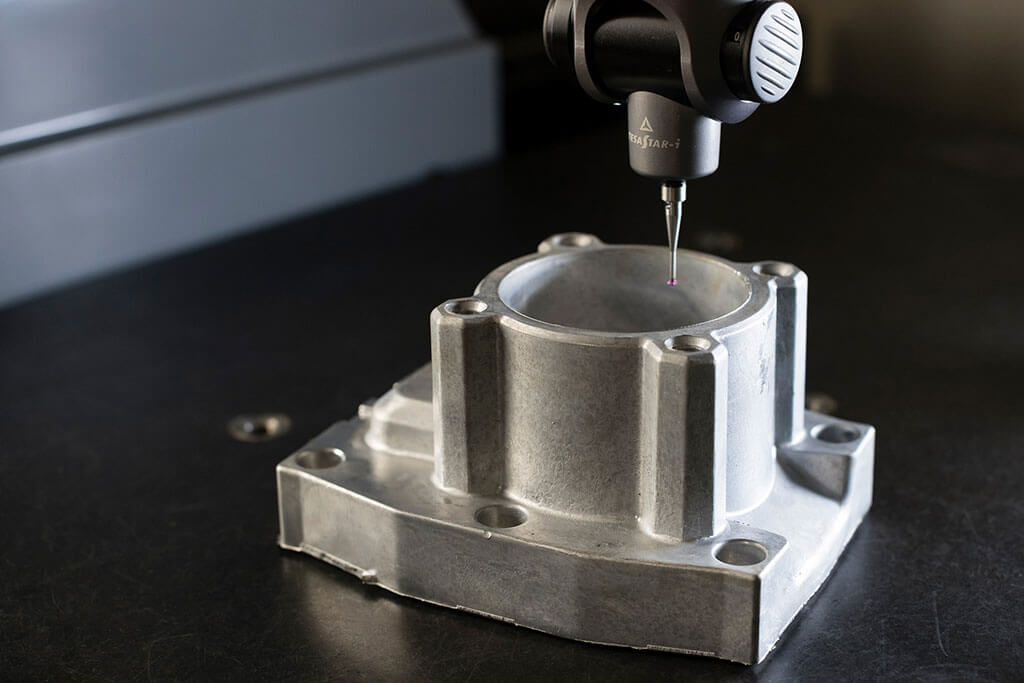

Incoming raw materials are thoughtfully checked through chemical analysis, micrographic analysis and thermal scanning.